Products & Service

Matching evolving products to support local pump manufacturing and the aftermarket has required travelling the globe to personally inspect manufacturers in U.K, Italy, France, U.S.A, Taiwan, China and recently Sweden.

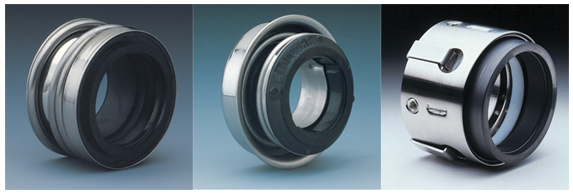

Our experience and knowledge has allowed us to identify and select manufacturers with the capacity to consistently produce the highest standard of componentry and finished product. These experienced manufacturers have well established quality control practices and form the basis of our comprehensive quality range of seals. This means that we can supply seals from some of the most respected manufacturers in the world such as Meccanotecnica, Huhnseal, Flowserve, Pac-Seal, Eagleburgmann and Vulcan. Our cartridge seals are uniquely sourced from Huhnseal (Sweden). Moreover our "independence" means we are free to provide you with the best solution from a variety of mechancial seal manufacturers and match the appropriate specification to your requirements.

Stock Range

We stock an extensive range of both metric and imperial seals with material combinations for a wide range of applications including agricultural, mining, pulp and paper, marine, industrial, chemical, food processing, domestic refrigeration etc. These could be for pumps, mixers, macerators, compressors, submersible pumps and gear boxes. Our seals are despatched throughout Australia and New Zealand for all popular brands including Onga, Davey, Waterco, TKL, Grundfos, Regent, Ajax, Southern Cross, Lowara, Dab, ABS, Mono, Flygt and many others including those for the pool and spa industry.

Seal faces and other components are part of our stock range and allow us to put together non-standard seal assemblies for same day delivery.

Over 90% of our orders are despatched on the same day basis.

Cross Referencing

Over the years we have developed a comprehensive cross reference to match seals for particular pump models, allowing us to quickly and accurately identify the seal required.

Material Specification Advice

Although most seal applications are for water some are selected for other fluids, including fuels, food products, process chemicals etc. We commonly recommend the appropriate materials or source according to customer specification.

Extreme applications often require the latest solutions and we can now offer "diamond coated" seal faces in our cartridge seal range (from Huhnseal Sweden).

We have superior options which are not available from other companies in Australia. This relates directly to the unique combination of features built into every Huhnseal E-Series cartridge seal. One of those features is the ability to tolerate +/- 2mm axial shaft movement.

Reconditioning and Failure Analysis

Seal reconditioning and seal parts replacement is a daily exercise for us with turnaround times rarely exceeding four days.

Failure analysis is freely provided. Seal failure is often not the primary cause of pump failure. If the root cause is not identified the failure will recur. Close examination of failed seals can give us many clues as to what may be compromising seal performance. We are happy to discuss the details of the application and determine what improvements could be made to the system or its management. A site visit could be indicated and is part of the support we provide to our customers.